I AM DECK BOX.

OK quick and dirty post.

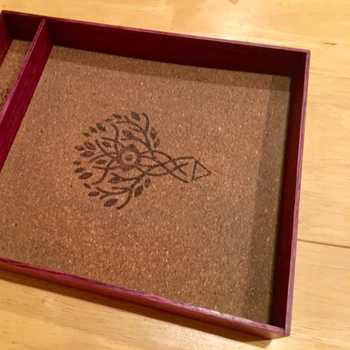

I made a MTG deck box out of bubinga. I stole some design cues about fingerjoints from @geek2nurse, but other than that it’s a fairly standard box, except for the closure system.

I elected to go with a snap-on leather retention belt.

Things to look out for which I may or may not have screwed up:

- Get the inner dimensions correct. Don’t waste materials on too-small boxes.

- Be careful of glue squeeze-out on the inside corners. It’ll get in the way if your box is fairly precise.

- Set your rivets accurately. They want to bend to a side, so make your holes in the side of the boxes accurate and tight, and set the rivets ramrod straight.

- I used satin wipe-on polyurethane instead of my usual oils, seemed like it would ruin cards if there were oil in the inside.

Other notes:

- Bubinga is a bear to cut, you’ll have to hit it pretty hard. As such, expect your kerf to be a bit wider than usual, if kerf correcting (which I’m sure you are, because craft. We’re not animals here.)

- Cutting your leather retention strap to the exact length needed is almost impossible to calculate. it has to do with how well your leather bends, the exact thickness of your material, how you sand corners, etc. I built the box first, then cut thin strips of leather to get a fit dialed in before I cut the final belt. I went a little short on purpose and rely on the natural stretchiness of leather to hold things together really solidly. (This technique was basically what I used on the D&D calendar too, but with an easier belt design that didn’t require as many precise metal fittings.)

Anyway, cheers. At its core, it’s just an engraved box, so without further ado:

A quick note about the rivets. I engraved slight recesses on the outside panels of the boxes to accept the “male” fittings, so that they would be flush to the box surface. The effect is that they look more integrated if they are just flat on top of the surface. On the inside, I had to take a drill and grind away some material around the lip of the hole, to allow for the little conical aspect of the post fitting. If this doesn’t make sense to you, it will once you try it. I could have flipped and done a second 3d engrave to remove some material, but a drill with a really big bit got the job done in about 10 seconds. The right tool for the job is key, and shockingly that is sometimes not a laser.

Bubinga, cowhide, brass fittings

Bubinga, cowhide, brass fittings

Bubinga, cowhide, brass fittings

Bubinga, cowhide, brass fittings

Bubinga, cowhide, brass fittings

A gift for a relative, it’ll be off to its new forever home soon enough.