Hi, I’m Chance.

I wanted to make something a bit more finished to celebrate the return of my Glowforge, here’s an idea I’d had kicking around for a while.

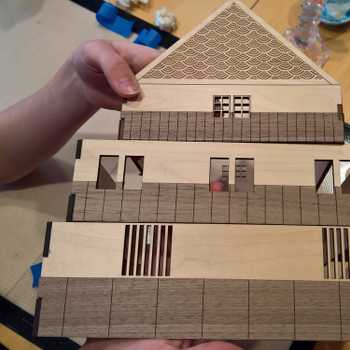

I wanted to make a layered, magnetically-sealed dice box, but I wanted to stay away from a few things I’d seen in other people’s designs. Specifically, I wanted to avoid the look of bare layers, and I felt like all other hex boxes I’d seen made were unnecessarily difficult to open because of the way you have to pull the magnets apart. The end result is you get a rough-looking box that probably flings your dice across the room when opening. This wasn’t going to work for me.

Notes:

- All woods used were 1/8" thick hardwoods from various sources (mostly Ocooch and Kim Oberlin)

- Ten layers thick.

- All of the layers were glued with Titebond original yellow wood glue.

- Registration is via 12 brass rod pins

- All exterior surfaces sanded to 600 grit

- The magnets are 3mm cubes.

- Wood finished with wipe-on satin polyurethane.

- Overall dimensions “point to point” on the hex: 4", 1.25" tall.

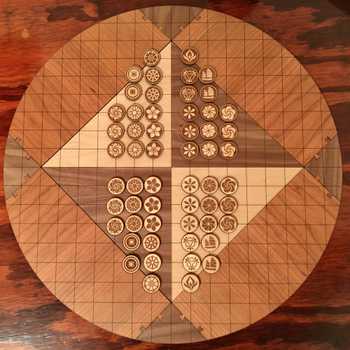

I wanted the box to be decorative, this is an interpretation of a classic islamic pattern that I found in a book. The intent was to get good contrast and keep the colors fairly muted so that padauk could really stand out. Yellowheart and walnut were natural choices in similar chroma ranges.

Walnut, Yellowheart, Padauk, Brass

Other boxes I’d seen made the hexes as small as possible, presumably to keep the dice from moving around and rattling. I had an alternate solution to that in mind, and wanted to ensure that the box would be big enough to accept slightly oversize dice.

Walnut, Yellowheart, Padauk, Brass, Oversized malachite dice

So, the solution I mentioned above was that I planned to line the box with headliner foam. This has two benefits: it holds the dice securely and prevents rattling, while also giving the box a finer presentation. I glued the foam in place using plain Elmer’s rubber cement, it’s fairly reversible should you ever need to replace the foam, rubber cement is easy to remove.

Walnut, Headliner fabric, Brass, Oversized snowflake obsidian dice

The design is an evolution of my knurled layered box, which enables easy opening/closing by virtue of the way you can spin the lid to disengage the magnets. You do not need to pull the halves apart. As a nice side effect, the lid can be used for a tiny rolling tray if you’re desperate.

Walnut, Brass, Headliner fabric, Gold glitter Chessex dice

I’d already experimented with covering up the layer edges in boxmaking, I wanted to change it up and also let the material take center stage. The layers started as slightly rounded hexagons, after sanding, they are smoothly fluted. Each layer was offset by 6 degrees, giving the box a smooth twist. It’s time consuming, I found that power sanders just don’t give you enough control – sometimes you just have to do it the long way. Maybe a spindle sander would work well, but I don’t have access to one.

Walnut, Yellowheart, Padauk, Brass, Synthetic howlite dice

Some detail to show the registration pins and the hex divider construction. Alignment is easy with pins like this. Only two pins are required, but I like the symmetry of six so I took the extra time.

Walnut, Yellowheart, Padauk, Brass, Enameled green/gold metal dice

A little more detail on the inlay. It’s challenging to get sharp corners and straight lines to present well, but I’m happy with the result. When you have it in your hand the imperfections (black fringing, overburn on sharps) are all but imperceptible; you only see the compromises when you are trying to find them.

Walnut, Yellowheart, Padauk, Brass, Chessex black nebula dice

So. Final thoughts…

- Triple check the polarity of your magnets before you glue anything together. If you discover that they’re wrong later in the assembly, you’re toast.

- Round the tips of your brass pins and use a drill to insert them. Trying to push them through with a solid friction fit just won’t work.

- Adhering each layer requires a quick hand; getting thin consistent coverage that doesn’t dry out before fitting is tricky. if I were going to do it again, I’d consider using a small roller to apply the glue.