It was a busy day at the 'forge today. We had breakfast guests and I wanted to demo my GF. They were all rolling eyes and “oh boy, she’s got another geek toy, we’ll humor her.” Everybody trooped downstairs after breakfast and they saw my samples and saw the possibilities. Starting to get excited. Then we whipped out a few quick items (a duplicate of the parametric box from @mpipes; a custom cake topper for a 40th birthday my sister was making a cake for). That’s when they really got it. I started getting orders for things to make already (can we make my Christmas gifts on that? Please?). Yeah. They skipped off before I could photograph the things.

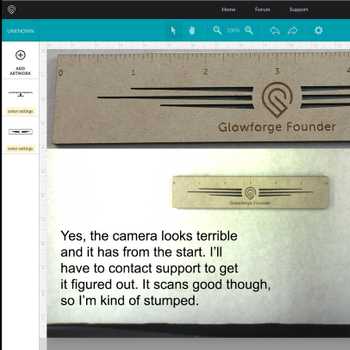

After they left I finished up the Illustrator file for my L shaped ruler I wanted. I cut it out of 1/8" Proofgrade acrylic. Here’s a closeup:

The tick marks were made by scoring, and it’s kind of cool that you can see the starts and stops digging deeper into the acrylic. I made the ends of the ticks just over the edge and I really like that the laser cut ridges along the ruler; it gives it a 3D functionality.

Okay, saved the best for last (at least for those papercrafters and rubberstampers among you). I’ve been anxious to try this Art Stamp laser polymer I bought from Jackson Marking Products.

Art Stamp Laser Polymer engraves like Standard Laser Polymer, but this material is crystal clear and the substrate backing is removable to allow the user to attach the die to an acrylic block for printing. Approximate sheet size is 7 1/2” x 11”.

They give you suggested starting speed/power settings. If you try this stuff, throw them out the window. They are way too strong. When I tried them the stuff melted. My second test was much more successful.

I created a file containing four boxes, each 0.5" x 0.25", and containing the word “test” set in 10pt Myriad Pro Regular. Converted text to outlines, cut the text out of the fills with Pathfinder, and reflected to produce a mirror image, thusly:

I pulled the file into the GF app and set the following settings, top to bottom:

- Power 1%, Speed 335, LPI 225

- Power 1%, Speed 335, LPI 450

- Power 1%, Speed 200, LPI 225

- Power 1%, Speed 200, LPI 450

Result was not bad at all! I’d like to go even lower in power if that were possible, but maybe I’ll test a lower LPI next time. There was a tiny amount of fine detail lost but considering this is 10 pt type, I’m pretty happy. Here’s the stamp and the stamped image using black ink:

If you are interested in trying this yourself, here is the svg file:

laser polymer test.svg.zip (1.8 KB)

Update: I repeated the test with power/speed at 1/335, using lower LPI settings; I think I like 195 LPI the best: