Supplies : Black 1/8" Acrylic Proofgrade (beta), Cork backing & acrylic paint.

Rockets. Everyone loves rockets. What makes a rocket cooler? Landing. Vertically. From space (Okay upper atmosphere… But still.) What’s even cooler? Landing a rocket from space on a ship. Not any ship- A DRONE ship.

So this is where this adventure starts. This story will have happiness, nerd rage and glee.

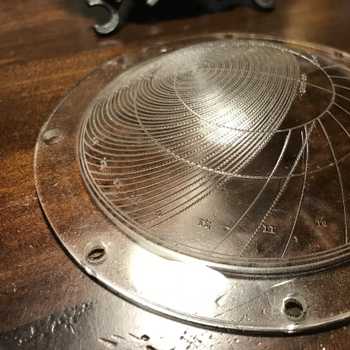

As usual I start out in Fusion 360.

I created a sketch and use the project tool to move all the details to one ‘layer’ and export it out as a DXF. Then import into Illustrator. This is only so I can add the text, color code and group up stuff so things get cut out in the order I want. Once I was happy with the layout I saved it as a SVG then send it out to the UI.

< Dig @ Glowforge > That AI plug-in would be pretty cool right now < /Dig @ Glowforge>

I hit the print button in the UI and see that the op is going to take about 2hrs. Okay Cool. Hit the button on the 'forge and and handled some support tickets for work. About 1.5hrs into the op I had to goto the restroom. (You know, typing that out on a forum seems- weird. But the point is I walked away from the 'forge.) I get back and noticed that the office is quiet. I look in the unit and find this.

Seems like the glowforge wanted to take a siesta.

I went into full nerd rage super saiyan 3. One. That was the last piece of black acrylic I had. Two. Why fail at the end? Why do it when I leave? (Anyone who owns a CNC or 3D Printer will understand this. Seems like these machines plot failure when you are not looking so you can’t see that the hell happen.)

Anyway. I was pretty done with it for the day and left it alone. The following morning my wife asked me I could do the same thing I did a couple years back when a friends CNC failed during a job.

Context : He was cutting out a irish family crest logo into a table top. His he was a little over 50% when his CNC died. And the top was supposed to be picked up 2 days later. So he called me and asked if I could finish it. I went over to his house and grab the table top and he have me the gcode he was using. Got home, loaded up the gcode in OpenSCAM (pre-fusion 360 days) and scrubbed thur it to about the point where his machine crapped out. Then truncated the gcode then ran it from there. Completed the job perfectly.

Well here’s the difference. The Glowforge does not use gcode. It uses magic. So- How do you append a failed op with machine that uses magic?

So the things I have. I have the source file and the part. I alt-tabbed to Illustrator and rescaled the image on my display to the size of the part that’s in my hand.

Then used the guide rule to line up to where the failure happened. Then used the trim tool to remove the area that was already engraved. Then removed the other assets that’s already been engraved. But I kept the cut line intact.

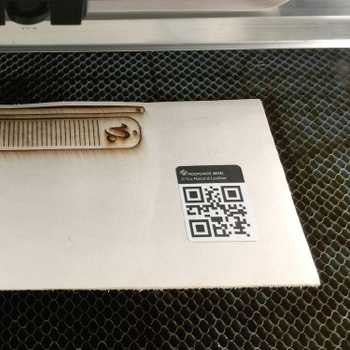

Loaded the 'forge with a fresh sheet of cardboard. Used some magnets to keep it in place.

I set the engraving to ignore and set the cutline to cut.

Pulled out my weeding tool so I can pull the inserts out with disturbing the jig.

Now I set the cut line to ignore and set the other asset to engrave. The picked ‘black acrylic 1/8"’ in the materials menu. Then loaded up the failed pieces.

Okay- I must have watched that preview playback at least 10 times before I pressed the button on the 'forge.

Okay- Lets do this.

Okay- Not quite. But pretty damn good. I mean the other option would had been to scrap it.

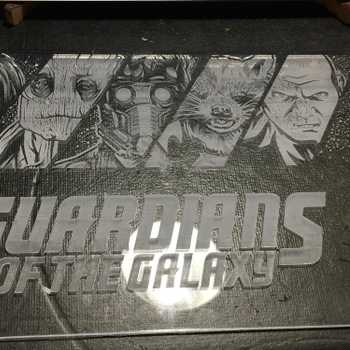

Now that the band is back together, I gave them a paint job.

Added a cork backing

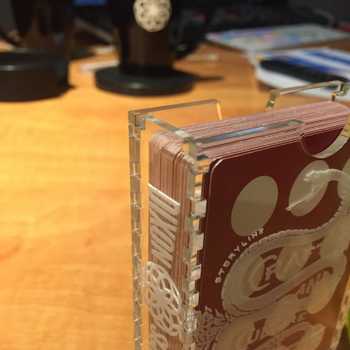

Glamour shots