Even before the  arrived, as the e-mails started to let folks know when they’d get their mighty machine, I knew that I needed a new, not-terrible belt pouch for my much-loved multi-tool.

arrived, as the e-mails started to let folks know when they’d get their mighty machine, I knew that I needed a new, not-terrible belt pouch for my much-loved multi-tool.

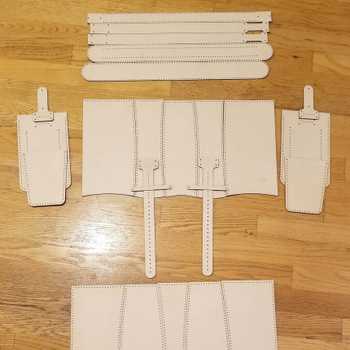

I’ve had the thing for seventeen years, and the nylon pouch with which it came has been replaced twice - it seemed to me time for something a bit tougher in leather. I had done some leatherworking as a teenager, and @dan’s wallet story reminded me that the worst part - cutting holes with a thonging chisel - was now easily automated.

I took some measurements, opened up OpenSCAD, and designed the shapes that I need. I mostly held the design in my head; the OpenSCAD models don’t tell you anything about how they go together. I just needed a way to precisely place and align things in an SVG - I’m no expert whatsoever at Inkscape (or for that matter, OpenSCAD)

I’d hoarded some leather scraps for a few years, so those came out, and rather than doing the responsible thing, I just told the machine it was “standard natural leather.”

The first attempt failed, but was really close to good. The problems I had were:

- OpenSCAD SVG export applies a “stroke” to the path, so without thinking I used Inkscape to “Stroke-to-Path” the thing. That doubled all the cut lines, about 0.5mm apart.

- Doubled cut lines dumped too much heat into the leather, making it very slightly more brittle, which wouldn’t have been a problem except

- My design had stitch holes 2mm apart and 2mm from the edges - that was simply too close. Leather failed around the tight curves, or sometimes simply from pushing the sewing awl through.

- 2mm stitch spacing just made this too fiddly to do with the big needle in the sewing awl.

So back to OpenSCAD to make some revisions:

- Recalculated for holes 3mm apart and from the edges.

-

vifor setting the units to mm, as well as for simply removing the ‘stroke’ elements from the paths.

Same power settings, which for this leather, simply weren’t quite high enough. I had to go over it with a razor to free the part. My fault, but lesson learned.

The holes were still a bit too small for this awl, but I decided that I could live with it. I had to figure out how to close the thing, though, and settled on a neodymium magnet which sticks to the multi-tool. I haven’t decided yet whether I think the fact that the pouch will not close without a tool in it is a bug or a feature  The magnet’s just very carefully glued in place; CA and hot glue. We’ll see if that lasts very long.

The magnet’s just very carefully glued in place; CA and hot glue. We’ll see if that lasts very long.

The belt loop part is two pieces, so that the pouch can be worn vertically or horizontally. This was a feature of the original pouch that I really appreciate.

And here it is, in place, doing its job, horizontally, just after I finished the magnetic closure:

Sources are here: