So we’re all locked down in this pandemic. My brother is home from work for the time being, and we realized we had the time and manpower necessary to install some track shelving we salvaged from my father’s house when he redid our old rooms. The problem was it was a ridiculous assortment of shelves of various widths, and most of them didn’t actually fit the brackets he found. (I have no idea how he managed to get six different size shelves and three different size brackets, but I digress.)

I decided to experiment on making my own brackets.

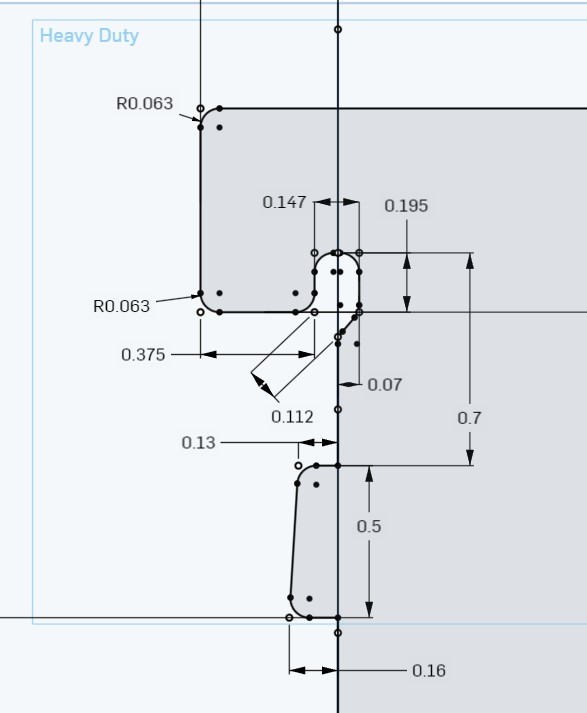

The first step was copying the geometry off the existing brackets. I used OnShape for that.

I used the measurements from a heavy duty shelf, because I figured the fact I was using plywood would mean I could use all the help I could get.

I’m using 1/8" plywood, which it turns out is a whisker thicker than the opening. (It’s probably EXACTLY the size of the opening, but then the powder coat narrowed the gap.) Initially I thought I would have to sand the tabs for a few seconds to get them to fit. Probably that’s still what I should do. But then I thought, why not do the silly thing?

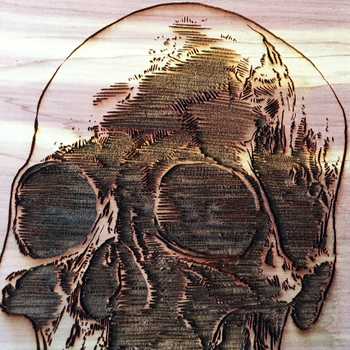

I engraved the tabs to thin them out.

If you look close, you can see the light line angled in from the top tab. That’s the angle I have to tilt the bracket to in order to insert it. In theory I should be engraving out to that line to make it as user friendly as possible. It still inserted easily enough. Getting it out was the more fiddly bit.

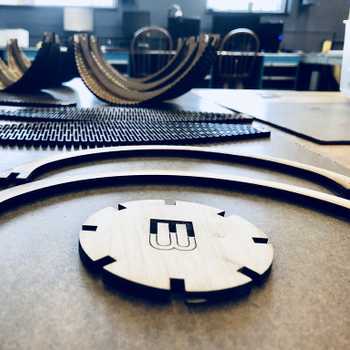

After some testing with a luggage scale, it seemed like a 6 inch bracket could handle about 16 lbs at the end before it started to buckle. I then made an 11 inch bracket, doubled it up, and did some cross bracing at the end to stiffen it and add a place for a screw hole to attach the shelf. I only braced at the end because the material is still a snug fit in the slots of the track. That means I have to be perfectly accurate with the width in order for both tabs to be able to insert. I haven’t honed in on adjusting for kerf yet, so instead I left enough un-braced wood to allow the flex to adapt to any misalignment. In retrospect, an inch of flex probably would have been more than enough.

I tested it with some 5 lbs weights at the edge of the shelf. No worrisome sounds or sagging. So I loaded it up with the lighter of the things I was planning to store and so far it’s survived a night without mishap. Both double brackets were lasered out of a single sheet of 12"x12"x1/8" plywood, so they cost maybe $1.50 per pair. I probably wouldn’t trust that shelf over 50 lbs or so, but it saved me a trip to the store during a pandemic, and honestly, 50lbs is still plenty.