Up to now I’ve only used Glowforge-approved PG material in my Glowforge Basic. But, then I was drawn in by a post here about a “sale” by Woodchuck’s Wood. Not the best experience. After cancelling the order they shipped me a stack of 1/4" and 1/8" cherry and walnut boards anyway.

Below is what I did with the stack of wood. All the coasters pictured are ~4" diameter. The “lasering” was done without any masking or pre-sanding of the rather rough walnut and cherry boards.

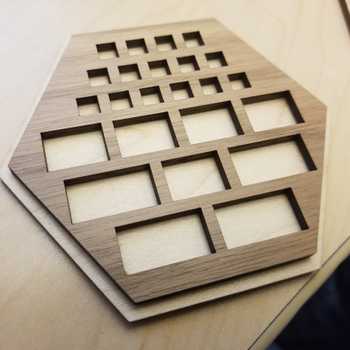

The above was cut from 1/4" walnut, using multiple passes to reduce “charring” in the kerfs. Required some serious sanding using by bench-top belt sander. Finished with Watco Danish Oil.

This cool Escher print already was in the shape of a coaster!

I like how the engraving using the 1/8" cherry boards turned out. To prevent the inevitable warping, I added a “ring” of 1/8" cherry with the grain rotated 90 degrees. I added a kerf-adjusted 3 mm acrylic window inside the wooden “ring” to protect the etching from whatever is placed on the coaster.

On the left is my first “test engrave”—which established very clearly that heavily etched 1/8" solid cherry warps!

On the right is the backside of the 4" Escher cherry wood “windowed” coaster. I used Inkscape’s “Hershey font” plug-in to create the text. I recommend “Path-Simplify” after placing Hershey text. When you need to add simple text to an item this font “scores” substantially faster than using engrave. Highly recommended.

These “L” (for Lightner) 4" contrasting wood coasters use two layers of 1/8" solid wood—walnut and cherry.

I purposely made no kerf adjustments to conserve material. Instead I mixed the wood filler shown with denatured alcohol to make a “runny” wood paste to fill the gaps between the two wood types. Not a perfect “fill” everywhere, but I learned enough to make it better (perfect?) next time. The 1/8" solid wood backing was glued to the pieced-together top using Gorilla wood glue.

Heavy sanding was required on the bench-top belt sander.

I like how everything turned out. I have not decided how to finish these coasters—maybe a simple clear polyurethane coating would be best?